Techflow Enterprises Pvt Ltd is proficiently one of the most reliable and prominent suppliers of products like Pulse Jet Bag Filter For sand blasting, Bag House, Centrifugal Fans & Blowers, Dust Recovery System, Air Pollution Control Device, Electrostatic Precipitator, De-Dusting System, Cassette Type Filter, Flue Gas Emission Control System, Online Cleaning Bag Filter, Bag Filter, ESP, Silo Vent Filter, Air Pollution Control Equipment, Welding Fume Extraction System, Pneumatic Conveying System, Fabric Filter, Offline Cleaning Bag Filter, Furnace Fume Extraction System, Reverse Air Cleaned Bag Filter Pulse Jet Dust Collector to various industries domestically and globally.

We at Techflow Enterprises Pvt Ltd have provided essential instruments to numerous industries like Air Pollution Control Systems, Cement, Kiln Exhaust, Mining and Minerals, Foundry & Steel, Particle Board Manufacturing, Coal Handling, Hot Gases and Fumes, Boilers Flue Gas, Solid Drying, Glass, Wood-Working & Laminates, and many more industries.

Discover more| Bag Filter For sand blasting |

|---|

In Pulse Jet Bag Filter For sand blasting, the spoiled air rushes through the cartridges and stores the dust molecule, assuring that only clean and foul-free air remains in the atmosphere. The cartridge type pulse jet bag filter for Sand Blasting has the perks of compact design and acquisition of less space. This is the significant reason why these systems are widely used in sand blasting, Powder coating, Shot Blasting, Mineral Grinding, Grinding & Polishing, Ceramics, Pigments & Chemicals, Food Processing, Engineering workshops, Polymers, Abrasive Manufacturing, Spices, Welding & Cutting, Pneumatic conveying systems, Grain Handling & Cattle Feed and plenty other. Techflow offers a vast combination of Pulse Jet Cartridge Bag Filter For sand blasting have a range between 1000 CuM/Hr to 1, 00,000 CuM/Hr. These Cartridge Filters are approachable with additional spares and substitutions like a technology of discharge device, surface filtration, and a variety of fabrics suited for various applications. |

TECHNOFLOW forms and supplies a tremendously efficient pollution control system. These systems are acknowledged by many names at national and international levels, such as Bag Filter, Bag Filter For sand blasting, Bag Filter Forsand blasting, ESP for a boiler, Bag Filter For Powder Coating, bag filter for boiler, Pulse jet bag filter, Baghouse, and De-dusting system.

|

1. Online Cleaned Pulse Jet Bag Filter For sand blasting

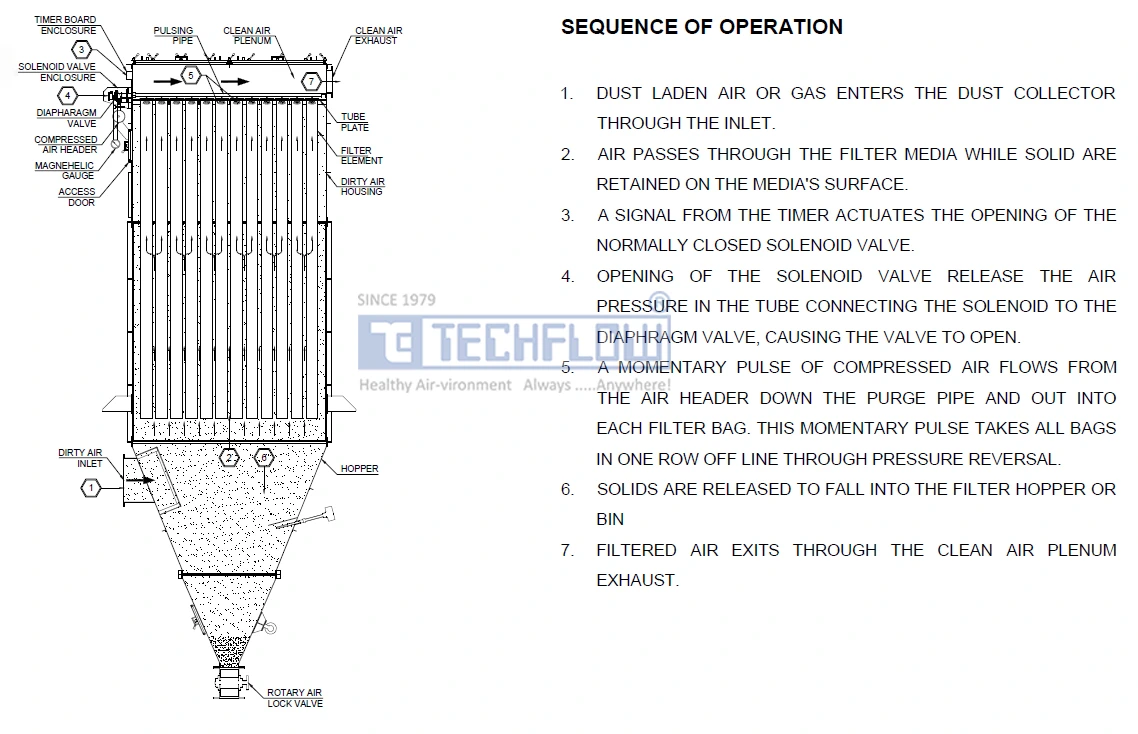

Where the heavy fragment, dumps out of the stream of air, the air which is stuffed with dust penetrates the hopper. The particles are heavy and stuck in the air which as a repercussion rises into the filter bags. The passing of air via the filter bags gives composed dust particles on the surface side of the filter bags as the cleansed air gets bushed via the collector. Jets of compressed high-pressure air pass through venturis thru the pulse valve and blowpipes, causing a solid flow of secondary air, briefly switching the airflow through the bags. This address the production of an innate shock wave that renders the bag compressed and mold outwardly as the shock hopped down the length of the bag. The procedure lets the dust eviction of the airflow which is inverted on the surface of the bag which then sinks into a collector called a hopper. Airflow through a row of bags is switched through this process, but only for a concise second. Throughout the collector of dust, this then gives a steady-state of airflow. Via a Solid State timer, the Cleansing Operation is easily modified and controlled. The perfect ordinance of the timer is enabled and managed by a differential pressure gauge. To lessen the consolidated air consumption in the process, the pulse gaps and durations can be exactly and entirely adjusted at the timer.

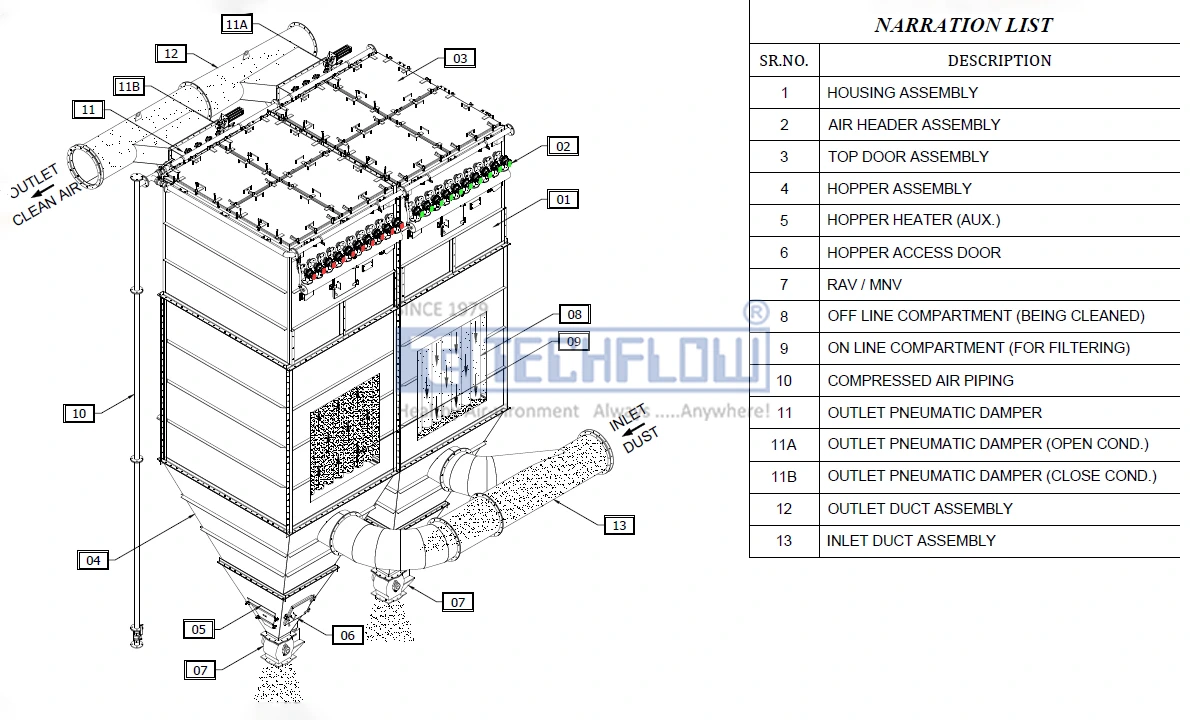

2. Off line Cleaned Pulse Jet Bag Filter For sand blasting

Separation of the Pulse-Jet baghouses is achievable too. In this case, the flow of the unclean air into the segments. It is controlled by the Isolation/Poppet valves residing in the pure air plenum. There is a choice to supply each of the segments either with the one single pulse valve that delivers the bunch of bags with pressurized air or have the fast pulsing air blown into the blowpipes that are further the bag rows in the element via personal pulsing valves. The airflow via the segment is blocked during the cleansing cycle as the isolation damper closes. For the cleansing procedure, an outburst of air is supplied into the bags through the entrance of the pulse valve for about two seconds. While the pulsing procedure, the segments stay offline. The time for that can be more prolonged or concise as required. The compartment is brought back on stream on the automatic reopening of the Isolation/Poppet. Via the process called Off-line Cleaning, until all the bags in the baghouse get cleansed, the alternate segments are consecutively cleaned. While the baghouse regularly achieves much lower emanation levels, It lets entire bag cleaning as it is oftentimes usees on fabric filters installed on less bulk density product/dust.